Delivering High-Tolerance Child Parts for Shock Absorbers through Advanced Simulation and In-House Tooling.

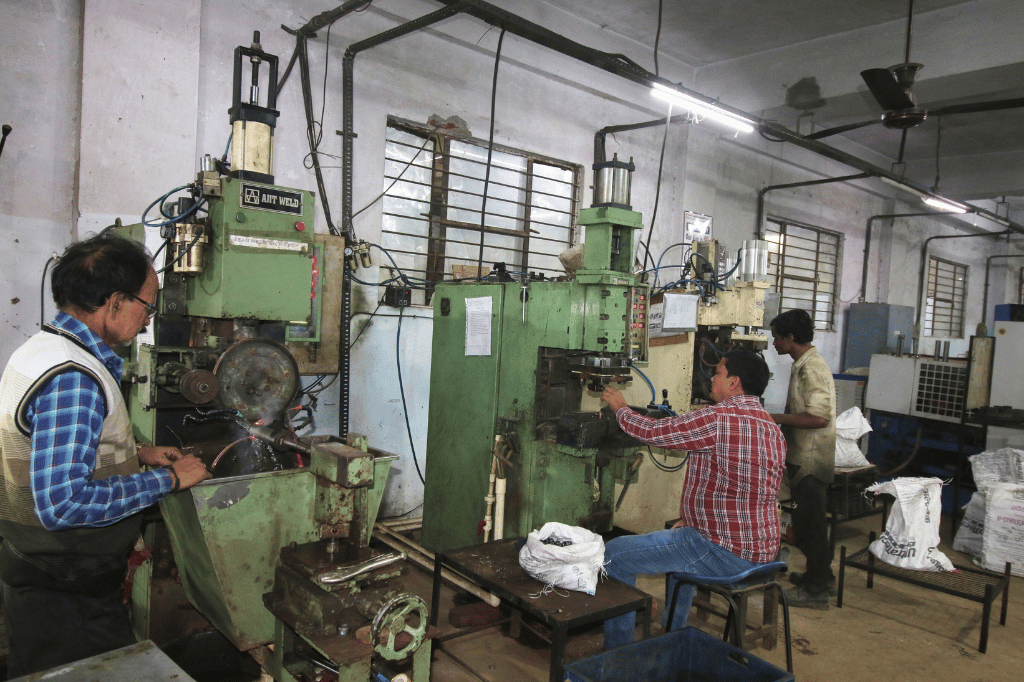

At Easto Pneumatic, we understand that a shock absorber is only as strong as its components. Our dedicated Stamping and Sheet Metal division specializes in manufacturing critical suspension parts that demand high structural integrity and tight geometric tolerances.

Unlike standard press shops, our facility is vertically integrated with our shock absorber production line, ensuring that every Outer Tube Assembly and Bracket we produce meets the rigorous fitment and durability standards of OEMs and Tier-1 suppliers.

With a focus on innovation, we are committed to developing next-generation shock absorbers for evolving vehicle platforms and global markets.

Micron-Level Precision Reliability starts with perfect geometry. Our machining shop is equipped with high-speed CNC Turning Centers and automated processing lines designed to meet the strict tolerances of OEMs and Tier-1 suppliers

Our skilled team works closely with the design and production departments to deliver tools that enhance quality, reduce cycle times, and support scalable production volumes.

Our welding section is powered by Special Purpose Machines (SPM) designed specifically for shock absorber manufacturing, ensuring leak-proof and durable joints.

Specialized Techniques: We employ a mix of Seam Welding, Projection Welding, and SPM MIG Welding to handle diverse assembly requirements for both light and heavy-duty applications.

Leak-Proof Validation: Every welded joint—from the base cup to the eye ring—is engineered for maximum strength. We validate weld quality through rigorous Penetration Tests and Destructive Testing (DT) in our quality lab.

Consistent Penetration: Our automated setups ensure uniform bead quality and deep penetration, critical for safety components in automotive suspension.

Integrated “Zero-Defect” Production. Our assembly line is the convergence of precision and control. As a vertically integrated facility, we control the entire value chain—minimizing external dependency and maximizing quality.

Superior Corrosion Resistance To withstand harsh environmental elements, we treat every product with an automotive-grade finish.

Our testing processes are designed to meet stringent OEM and export standards, ensuring each shock absorber performs reliably across all vehicle applications.

Manufacturers and Exporters of high-performance shock absorbers for 2, 3 & 4 Wheelers, Heavy Trucks, Trailers, CNC Machined Auto Components & Sheet Metal Auto Components. Trusted by OEMs and global partners for quality, durability, and precision engineering since 2008.